Solution

MARPOL Facility

Scroll Down

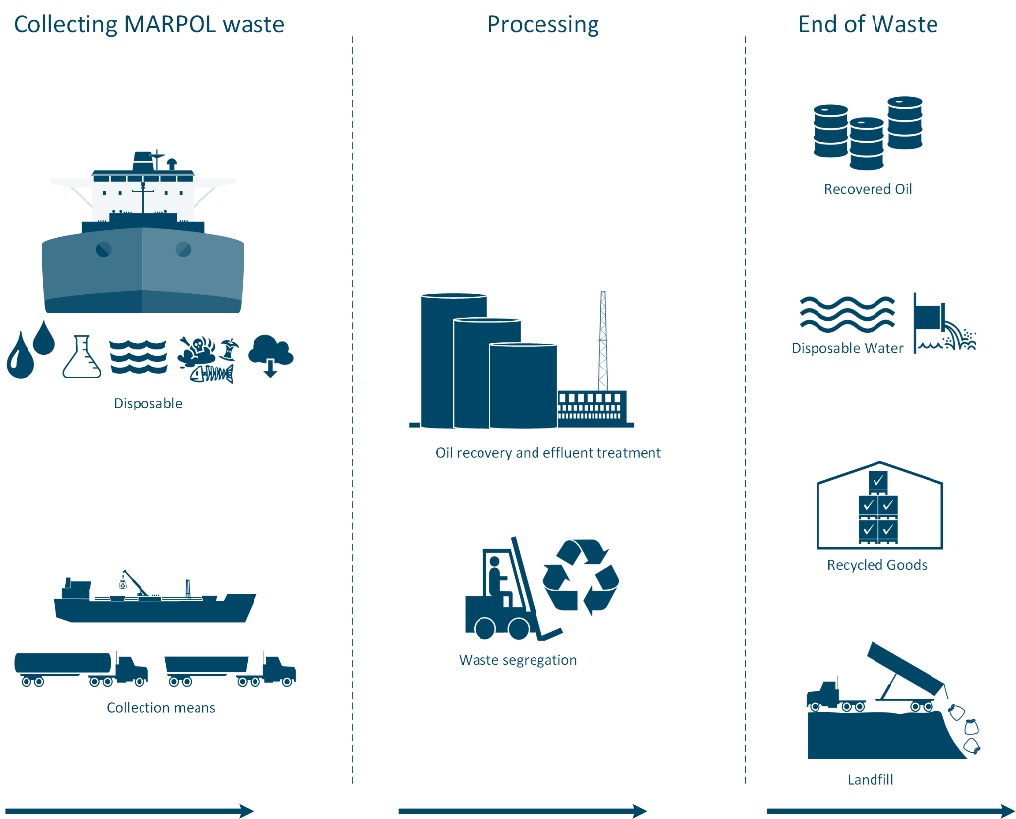

Fuel recycling in MARPOL waste facilities using gravitational methods primarily involves separating oil from water in ship-generated waste through gravity-based processes.

This technique is widely used because it’s cost-effective, energy-efficient, and suitable for handling large volumes of oily waste, such as bilge water and slop oil.

Gravitational Separation Process

Solids that settle at the bottom of the tanks or separators are removed and often treated as sludge waste. In some cases, sludge is dewatered, and any residual oil can be recovered through further treatment. Dewatered sludge may then be incinerated, disposed of, or processed further depending on its composition.

1. Collection and Initial Settling

2. Collection of Oily Waste

3. Settling Tanks

4. Oil-Water Separation

5. Gravity-Based Separation Units

6. Skimming Oil

7. Centrifugation for Enhanced Separation

8. Polishing with Centrifuges

9. Residual Water Treatment

10. Sediment Removal

11. Blending and Use of Recovered Oil as Fuel

Advantages of Gravitational

Separation for MARPOL Facilities

- Cost-Effectiveness

- Simplicity & Scalability

- Eco Friendly